Electric arc metallization kit

Specification

|

Power supply |

3 P 50/60 Hz 400 V |

|

Power |

21,1 kVA |

|

Security |

35 A |

|

Metallization current voltage |

15-42 V Smooth adjustment |

|

Metallization current |

max. 430 A for 100 % load |

|

Working temperature |

-10 to +40 °C |

|

Power supply weight |

62 kg |

|

Wire diameter |

2,5 mm (optional 1,6 mm) |

Why is it worth investing in our Electric Arc Metallization Kit?

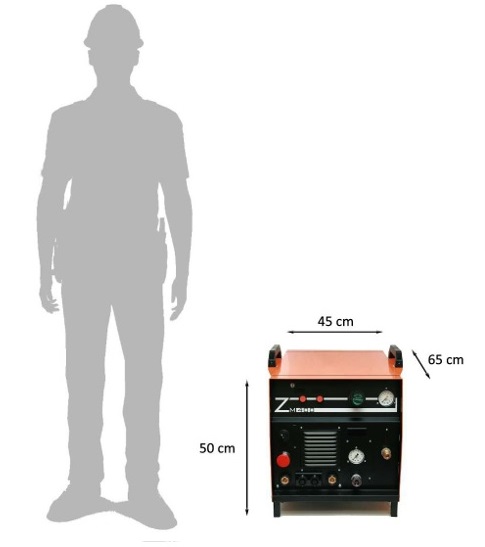

- Small size compared to other devices of this type

- High performance (definitely higher than with flame metallization)

- The possibility of securing large-size structures

- Very high durability of the coating and resistance to mechanical damage

- No thermal deformation of coated elements

- The possibility of additional protection at joints or in places of mechanical damage

ATTENTION! We also manufacture and install blasting chambers and dust collectors fully adapted to the metallization process. You can read more about our chambers here.

Description

The set for arc spray metallization is a complete device used for making zinc, aluminum and zinc-aluminum anti-corrosive coatings. Thanks to the use of modern technology and patented solutions, this device is extremely light and small compared to other similar devices on the market. This makes it an extremely mobile and comfortable to use!

Our metallization device has a 20 m range, further increasing mobility and work comfort. The use of such a long cable harness ensures that the machine can be positioned at a sufficient distance to protect it from excessive dusting.

The use of modern technological solutions allows the operator to maintain an appropriate arc and even metal spray on the surface. What’s more, the control unit ensures that the wire is fed at a constant speed. In addition, smooth adjustment of spray parameters means that the device instantly adapts to all materials used in spray metallization.

Considering the above, when you decide on a device for metallization in our company, you get safe and efficient equipment, at the same time convenient to use, thanks to which you can ensure a constant thickness of the sprayed coating!