Abrasive recirculation systems

Specification

Abrasive Recirculation System is manufactured to order according to investor’s guidelines.

Why is it worth investing in Abrasive Recirculation System?

- Comfort of work. With the abrasive recirculation system, no time is wasted on repeatedly backfilling the abrasive tank, which significantly increases the quality and efficiency of work.

- Economic. High-quality abrasive materials can be used up to several hundred times!

Guarantee of quality

Our many years of experience in the production and installation of Abrasive Recirculation Systems and the use of components from reputable companies (Schmidt, Airblast, Clemco, Semperit) guarantee high quality!

Description

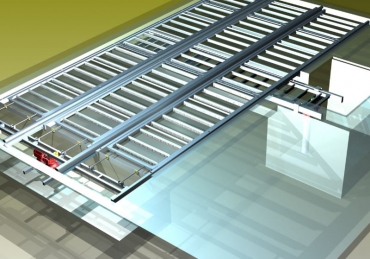

The Abrasive Recirculation System is a solution that transports, separates (regenerates), stores and delivers the abrasive during blasting in the Shot Blasting Chamber. Such a system may consist of the following elements:

- Floor scraping system – used to collect and remove abrasive from the floor of the Chamber. Depending on the purpose, this system can cover the entire surface of the Chamber.

- Bucket elevator – maintenance-free, electrically driven transport of abrasive from the floor to the abrasive separation system.

- Abrasive separator with rotary screen (optional magnetic) – a device which, together with a dust removal system, ensures that the abrasive, once used, returns to the circulation without dust pollution.

- Hopper tank – a container for transported from the chamber and cleaned abrasive, which automatically fills the cleaner ensuring continuous and uninterrupted operation.

Such a set, described above, can work in a “closed circuit”, which means a continuous and non-human intervention of the abrasive circulation.