Abrasive blasting

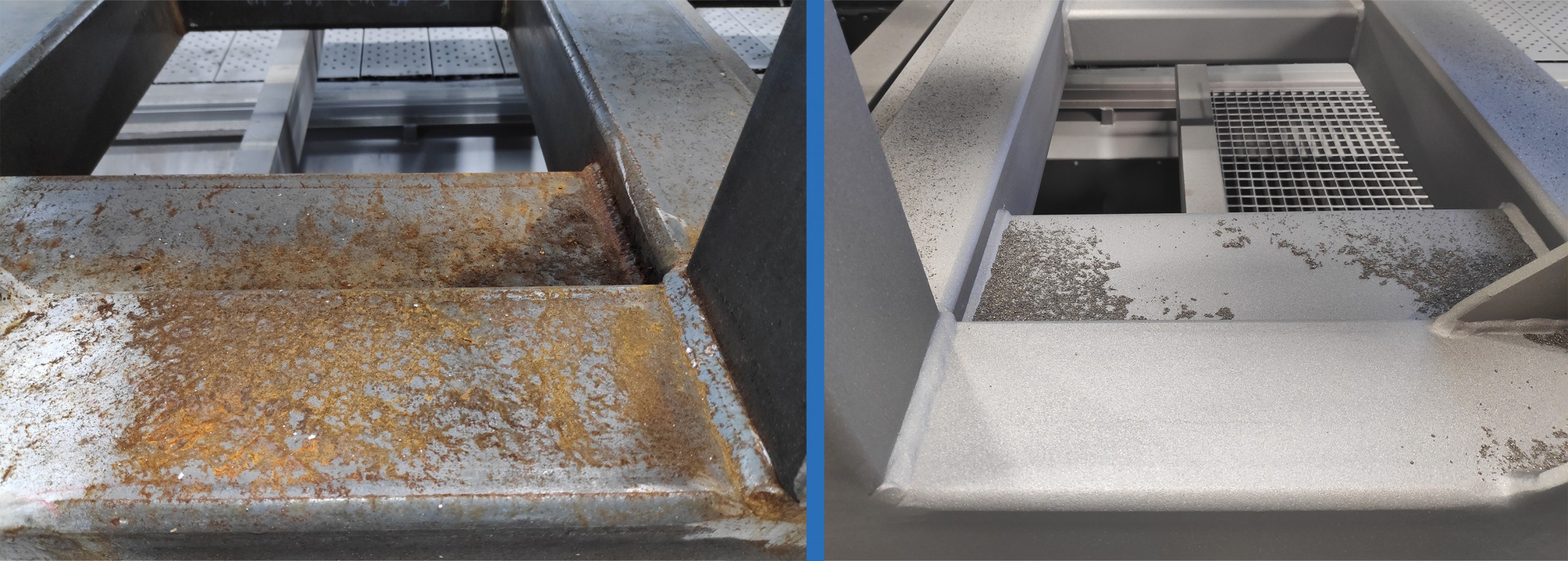

Abrasive blasting, using compressed air to impose an abrasive material on the surface to be cleaned. As part of the abrasive blasting service, the following services can be distinguished:

- Shot blasting (commonly called sandblasting), consisting of preparing the substrate for painting, as well as removing dirt, varnish coatings, etc. In the case of sandblasting, various types of abrasives are used, e.g. mineral abrasives, such as sand (quartz), aluminum oxide, soda, glass microspheres , or non-mineral abrasives, such as copper slag, steel shot, stainless shot and others. Surface cleaning using abrasive blasting is carried out wet (mandatory in the case of sand cleaning) or dry (for example in a specially prepared shot blasting chamber, where it is possible to recover and reuse the abrasive). For more popular abrasives, please click here.

- Soda – the use of baking soda with the chemical formula NaHCO3 in blasting is an increasingly popular method among our customers – especially in the automotive industry. This is due to the fact that soda is harmless to the environment, soluble in water, as well as properly used, does not affect the surface being cleaned. Thanks to this, the sandblaster can be used in an open space without worrying about the environment or the operator of the device.

- Sprouting – a method involving the use of special abrasives (such as glass, ceramic, plastic shot) to standardize the substrate made of stainless steel or aluminum and achieve a satin finish. To achieve a better visual effect, prior to the slide process, the surface is pre-cleaned using aluminum oxide – extremely hard and durable abrasive.